The head motor fails to rotate, the unit therefore shuts down a short while after

any transport mode (play, wind etc...) is activated.

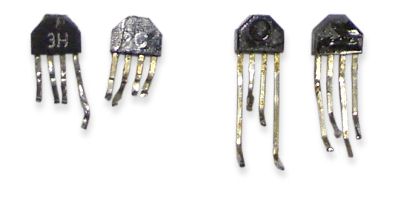

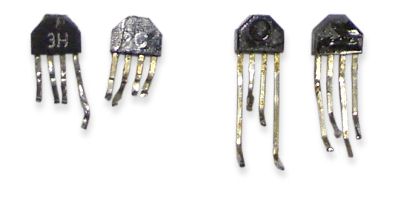

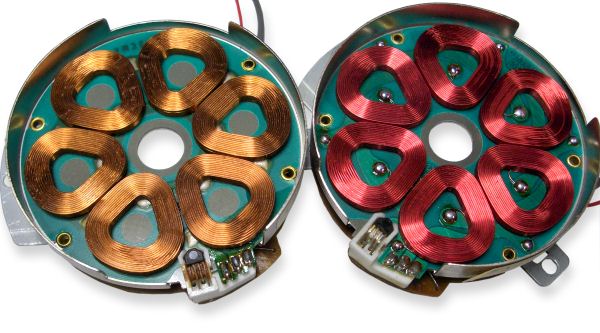

More often than not, the

Hall effect sensor

on the motor fails and will need to be replaced. This is a small, 4

legged component that can be seen on the right hand side image in the

white area at the bottom.

Hall effect sensors can be difficult to source, although with care,

spares from other models can be used (such as from Sanyo and Toshiba).

The part number sometimes listed appears to be the HTS-103A (per Sony circuit diagrams).

This though might be in error, the correct part could be THS-103A (seen on AliExpress).

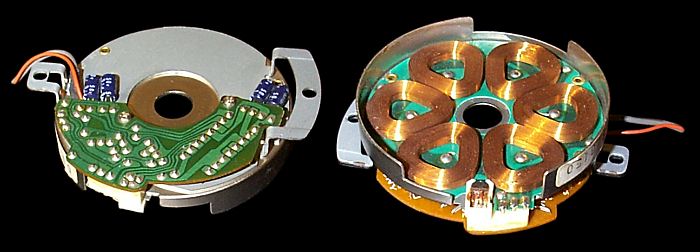

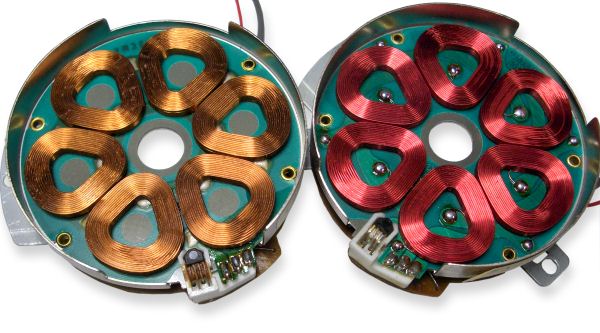

The left 2 images are taken from a Toshiba drum motor.

The right 2 images are taken from a Sanyo VTC-M20 capstan motor board.

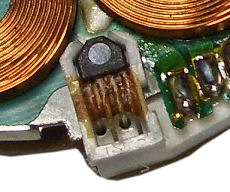

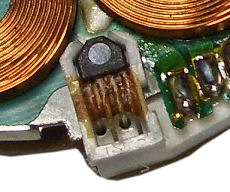

In a few cases, the device can be made to work again by scraping away

the glue attaching the device to the board. This glue sometimes becomes

conductive shorting out the electrical signals. This is prone to occur

when the unit has been in a damp environment resulting in moisture being

absorbed by the glue. It is recommended to remove this glue.

Hall effect sensor attached with glue

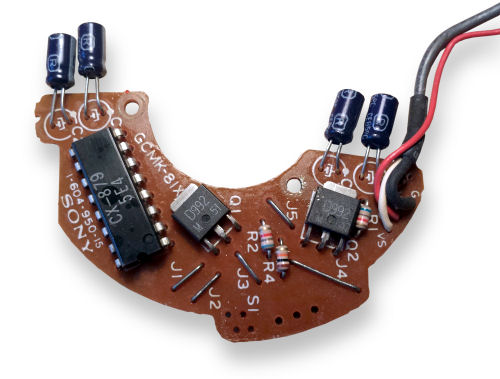

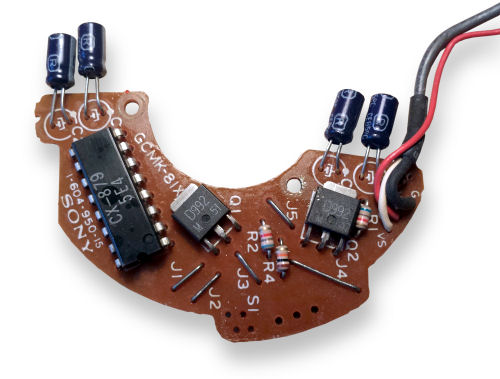

The motor can also fail due to dry solder joints or when the

electrolytic capacitors dry up. The coils connect to the 3 pin block on the circuit board, and the hall effect sensor to the 4-pin block.

Hall effect circuit board

From left to right: Capacitors 1µF, 1µF, 0.1µF, 0.1µF all are rated 50v

If both of these approaches fail, it will be necessary to replace the

sensor with a second hand one taken from another machine. There are

various designs of hall effect sensors, but if it looks the same as the

Sony one, it will probably be compatible.

These other units tend to have shorter leads which will need to be extended to

fit the Sony. A trick for fitting them is to use four

Teflon coated wires (wire wrap type) stripped bare for a suitable length

and passed through the four mounting holes on the drum motor board. Then

solder these to each of the device legs taking care that they are bent

to replicate the original pattern and clearance for the legs. Next draw

the excess wire back out of the holes to pull the hall sensor in place

and bend over each wire on its pad then solder / wriggle / break the

excess wire off.

The correct orientation for fitting the sensor is with the lettering

side not visible.

To remove the board you need to (whilst having the machine in the best

orientation to do each task):

- Take off the case bottom cover.

- Remove the screws and flap out the small circuit board covering the reel

assembly/capstan and drum motors.

- Remove the drum nut and magnet being sure to put aside the washer

beneath the nut and on the shaft under the magnet.

- Top side of the machine, unscrew and fold out the tuner board.

- Disconnect the three wire drum motor drive lead (white three pin

connector with red lead and grey/white screened lead).

- Top of drum note the arm positions for the post guides then loosen the

left hand side (first guide and swing it away from the white upper tape

edge guide) .

- Swing aside the earthing bar out of the way of the drum and remove the

two screws and the white upper guide.

- BEING VERY CAREFUL NOT TO TOUCH THE VIDEO HEADS OR LET THEM HIT ANYTHING.

- Get as much slack as you can in the remaining leads to the drum and

remove the three drum retaining screws with springs and washers.

- From above the machine carefully lift the drum assembly out of the

machine so you can access and remove the two screws holding in the drum

circuit board .

- Below the board open the white catch holding the cables and remove the

circuit board.

- Assuming the machine is right side up, rest the Drum assembly back in

the machine (for safety of the heads)

- Repair the circuit board by replacing the hall effect sensor. Remove all

the glue holding it in place. It is probably not necessary to reglue the sensor,

instead rely on lead tension to hold it in place.

Installation is the reverse procedure, again taking great care not to

damage the heads.

The left drum motor is faulty (note glue still on sensor.)

The right motor has been repaired. (wire colour makes no difference, the boards are the same.)

Thanks go to Noel Higgins for supplying this information.