Technical

SLO-420P rear view |

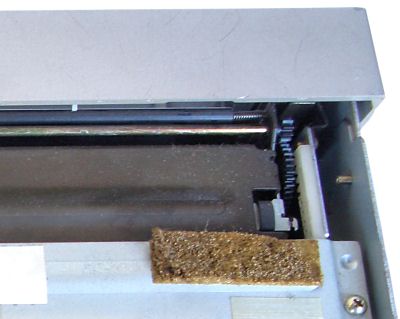

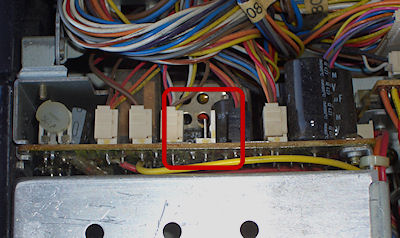

REMOTE / TV connectorsThe major difference on the rear of the SLO-420P to the SL-C9, is the addition of the REMOTE and TV connectors used to connect the unit to an edit controller. Internally these connectors are hard wired onto the audio and servo boards (SS11) enabling the remote control and other AV connections of the machine via the blue REMOTE connector and green AV TV connector at the rear.There is also an Rx switch which replaces the SL-C9's PCM switch. This is used to switch the machine when under hard wired connection to send or receive data. The two circuit board images show the audio and SS-11 boards with the additional wiring for the connectors. Click to enlarge. Multi-Out ConnectorThe 8-pin Din Connector is known as a Sony Multi-connector and carries a combined Audio, Video and Remote control (later known as CTRL-S) signals. Details of the pin connections are available online. |

PSU connections |

Power supply unitLooking at the power supply unit on the SLO-420P, it appears identical to the SL-C9's. As the SLO-420P does not have a tuner board though, you can see that there is a missing connector on the board.Additional remote control functionsAlthough not available using the supplied remote control handset it is possible to operate eject mode via a remote control. This code can be found on some modern universal remote controls such as the One for All. In addition one of the channel advance functions of the SL-F1 remote works on the C9. |

Upper drum |

Fault and repair guideIrregular tape transport during rewind/review.This is cause by the tape which tends to stick to a worn upper drum. It can be fixed by replacing the upper drum. Sony now supply an improved type which is made of a harder wearing alloy.The picture opposite shows the new upper drum which no longer has a mounting plate. |

Broken gears on the carriage causing noisy loading

|

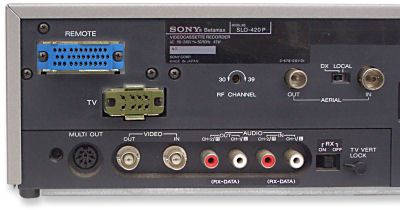

Defective loadingThe plastic gear on the cassette carriage often breaks. This usually leaves the tape trapped in the machine and if tape eject is attempted it can result in more broken parts (such as the inner and outer cassette flaps). Sony supply a 'carriage modification kit' which contains an improved set of gears and unlike the original are made of metal as opposed to plastic. To fit this kit the carriage must be removed from the deck. This can be a tricky job because the front panel must be removed first. If you attempt this task then pay special attention to the rod which connects to the bottom of the carriage before removal.Dec 1997: The kit is no longer available from Sony. The picture shows a complete carriage. The circled areas shows the location of the loading gears. Unlike the SL-C9's white gears, the SLO-420P for some reason used black loading gears. Perhaps these were less prone to break? |

Threading gear |

Grating noise during tape threading / unthreading.This is caused by a split threading/pulley gear. Repair is by replacement. It advisable to replace the threading belt at the same time.

|

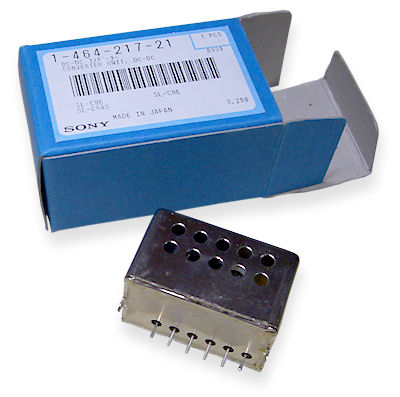

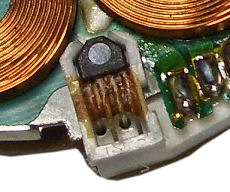

MKII DC to DC converter See also the parts page |

No fluorescent displayThis is caused by failure of the DC to DC converter in the power supply. This is a sealed unit which is extremely difficult to open and can seldom be repaired if successfully opened. Sony supply an improved replacement which can be identified by the air holes along the sides. The original unit was completely sealed.It has been known for these replacement units to fail after a few years operation. However, unlike the original ones they can usually be repaired by replacing the reservoir electrolytic capacitors inside. The DC to DC converter also supplies the tuning voltage hence when it fails no channels can be received. Dec 1997: The DC to DC is no longer available from Sony. Take a look at the DC to DC converter page for full information on fixing the unit. Including circuit diagrams. Reel spools running continuously.This can occur when one of the reel motor mute transistor fails. |

Hall effect sensor attached with glue |

No head drum rotationYou may find that the head drum fails to rotate. This is due to a problem with the Hall effect device on the head drum motor which is secured by a blob of glue. Full details on how to fix this can be found on the head motor page. |

Quick fault guide

Please click on the button if you are able to contribute a solution to this list or would like to add to, or update PALsite's information on this model. Please note, questions will be removed.If you have a question about this model, please raise it on the chatpage.

| Fault | Solution |

|---|---|

| Blank unmodulated raster on playback of own recordings | Clean or replace the audio/control track head |

| Capstan running fast in playback and record | Check IC006 for failure |

| Capstan running slow | Check IC002 on the SS11 board for failure |

| Chewing tapes | Check the condition and positioning of the pinch roller |

| Clock incorrect and flickers during recording | Check IC601 on panel SS11 for failure. |

| Colour patterning on picture | Check IC605 on panel SS11 for failure |

| Eject LED flashing at switch on then goes into standby | Suspect excessive friction in the front loading mechanism |

| Intermittently ejects tape | Check transistor Q633 for failure |

| Intermittent loss of display when warm | Check for failure of IC201 on the TM31 panel |

| Intermittent loss of e-e picture | Check filter SF001 on tuner panel for thermal failure |

| No or incorrect colour in playback | Check resistor R114 for failure |

| No or loss of picture, no colour during playback | Check capacitor C38 on the RV7 board for failure |

| No capstan motor rotation | Check fusible resistor R530 (0.2 ohm on SS-11 board) for open circuit. Replace it with an electronic fuse (Sony part: |

| No picture during playback of colour recordings | Check for failure of IC005 on the RV7 panel |

| No remote control operation | Check capacitors C203 and C204, if OK then check IC201 |

| No sound in playback or e-e | Check diode D515 on panel AM1 for failure |

| No tape remaining indicator | Check IC501 on panel JR for failure. |

| Permanent drum rotation | Check resistor R329 on panel SS11 for failure. |

| Poor or low sound, back tension setting and audio head ok | Check for correct operation of op amp chip IC520 (UPC14581) then check switching chip IC521. |

| Poor or noisy pictures | Clean the tape path then check the setting of tape guide no. 5. If OK check for dry joints around transistor Q701. |

| Self switching to other functions, LED's flashing at random | Check IC601 on the SS11 panel for failure |

| Stops after few seconds, no tape take up | Check fuse F001 on the SS11 panel for open circuit. |

| Will not load tape, eject LED flashing | Check the unload end switch for poor contacts failure. |

| Will not switch on | Check capacitors C203 and C204 if OK then check IC201 for failure. |

| No power up. Front panel LEDs not alight | Check mains switch at rear of unit is set to on. |

| cant load tape | If you can`t physically get atape into the slot more than half way (ie past the guides above the tape visible when cover is off) These are two small pieces of silver metal with a black rubber band round them either side of the carriage - One of these may have dropped lower than the other, preventing a tape being inserted.

I have seen 2 c9s like this. In this case, get a finger round the back and push this guide up as you insert a tape. The motor will try to take it after the tape has gone under the guide. Push the tape in with adequate force, but don`t push too hard. If you get it right, the tape will load and thread up normally. Then, look directly below the 3rd tooth of the "L" shaped plastic gear which is mounted on the side of the carriage, you will see a small metal lug in the same place on each side of the carriage. This lug should point 90 degrees into the carriage. One of them will be bent, probably to only a 45 degree angle. Use a flat screwdriver or similar to bend it back to 90 degrees. When you are happy both lugs match eachother, eject the tape normallly. The vcr should now load tapes normally. |

| split threading gear | If you have a split threading gear (grating sound when threading and unthreading) it nneds to be replaced. Undo the two screws holding the haed amp can, then lift it over on its hinges. The split gear is the larger of the two black pulleys you see with a band betwen them. Lift the band off the large pulley and then use a small screwdriver to lift the o ring off the top of this pulley. The pulley will now lift easily off. Replace making sure the teeth of the two gears mesh. Refit the o ring and refit the band. |

| That clunky, twangy sound on rewind/f.fwd | Don't panic! You probably don't need a new upper drum ass'y. I used to work on these machines when they first appeared on the UK market and even then, (often under warranty) we used to get quite a few C9/F1's with this fault! (The other common one was dried up electrolytics in the PSU). I was an apprentice at the time, and my "boss" showed me this simple fix which I never forgot; thouroghly 'scrub' the upper drum with an ink rubber, yes, an ink rubber! Preferably, one of those that looks like a white 'pencil'. It works, honest! Obviously avoid the heads; I am still running a C9 today (something you can hardly lift has got to be good, innit). Have fun! [email me: [email protected]] |

| No freeze-frame advance or 1/10th speed, but 1/5th OK | If freeze frame forward/back and 1/10th speed do not work reliably or at all, even though 1/5th works, a slight anticlockwise adjustment of RV017 on the JR-1 board (underneath the tuner panel) should fix it. |

| Muffled audio, may be intermittent | Muffled sound on good recordings, which may be momentarily overcome by applying gentle pressure to the top edge of the tape as it leaves the audio/control head, is of course usually caused by audio head wear (even if the heads look perfect). Head alignment is the other possibility but should be right unless someone has been twiddling.

Replacement of the A/C head is a fairly major undertaking because the cables weave all over the shop. Remove the loading motor to gain access to the cable run beside it. Though the cables are routed along with the erase head cable, the latter is not connected in any way and its cables can be refitted after A/C head cables have been installed. Both bottom panels need to be swung out to gain access to connectors because the control head cable goes one way (through cable ties too) and the stereo audio cables go another. The A/C head assembly all comes off with just the two screws on the top plate (one has a black earthing wire with it). Care not to misplace the shims under the top plate. Little or no A/C head alignment should be necessary after replacement. |

| Cassette loads but won`t thread | Either it is the threading motor which is faulty, or possibly the metal bar which connects to the bottom of the cassette bay from the right hand side of the carriage could be bent. This bar could have got bent if the carriage has been replaced at some point. Remove the carriage and check that the two parts of this bar are not bent. If so, straighten them and reassemble. |